Submerged Scraper Conveyors

KNEPREMIUM

Ash extracting conveyors of different systems belong to the product range and delivery program of MICONTEC GmbH. These products are for both the extraction of combustion chamber ash and the transport of all other ash residues of coal-fired steam generators and waste incineration plants. To ensure high availability of the plants conveying components have been developed, which guarantee reliable operation and are economically justifiable with regard to power requirements, operation, maintenance, repair and investment costs.

Submerged scraper conveyors

Submerged scraper conveyors are the most used ash extracting conveyors for the disposal of combustion chambers.

With design differences depending of the material to be conveyed, they are used for granulated slag, ash from black- and brown-coal fired boilers as well as for the transportation of waste-ashes and smelting-residuals.

Details:

Submerged overhung stations and idlers

Submerged overhung stations and idlers belong to the most important components of scraper conveyors.

In the last few years MICONTEC GmbH has developed and significantly improved these key components in cooperation with plant operators by improving the used materials and the reinforcement of the bearings. Through various innovations such as rotation monitoring, sealing-water connection and external bearings the operational reliability and high availability of the scraper conveyors are guaranteed even in difficult operating conditions.

Details:

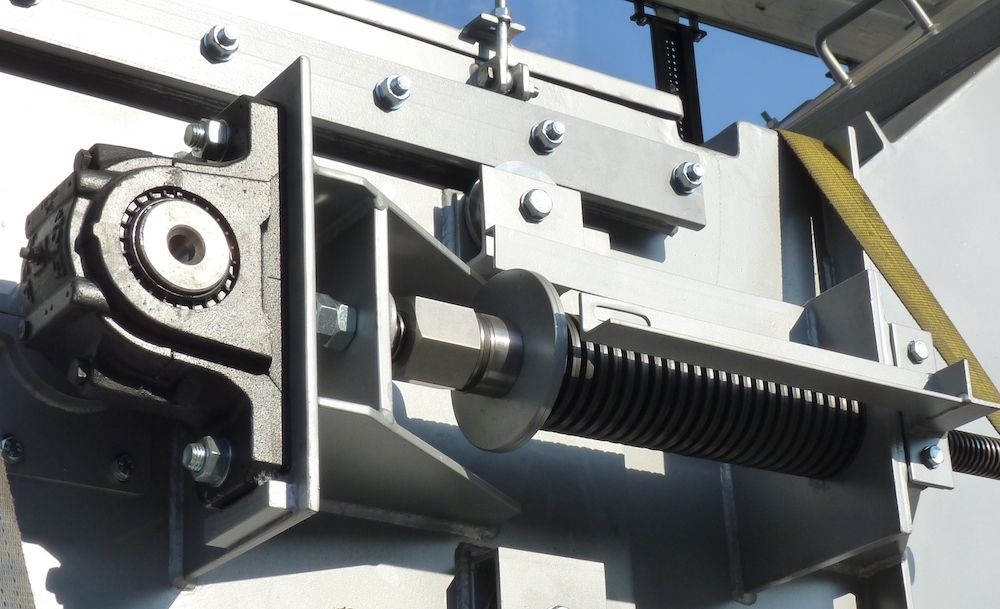

Hydraulic tensioning stations

Hydraulic tensioning stations increasingly displace traditional spring-loaded tensioning stations due to the fact that in contrast to the mechanical variant they guarantee a constant equable tension of the conveyor chains.

This continuous optimum chain tension makes its decisive contribution to the operational safety of the conveyors. The constant availability of the hydraulic tensioning stations is guaranteed by various security systems such as detection- and alarms-features as well as control-check-valves installed at the hydraulic cylinders. Apart from the design and supply of complete hydraulic tensioning stations MICONTEC GmbH offers also the modification and installation of these components.

Details: